We spend significant time pondering helpful content that will educate consumers about the options available to upgrade their car audio system. We’ve written dozens of articles explaining how various features and designs can improve a subwoofer’s performance, and we realized that this would be a perfect time to summarize all that education in a single document. Welcome to the ultimate guide to subwoofer performance technologies!

Subwoofer Performance Means Different Things to Different People

We’ll review several design elements that affect a subwoofer’s performance, linearity, accuracy, efficiency and cost. Some features make a subwoofer more accurate. Others make it more efficient. Most add to the cost. We’ll simply define the benefit. It’s up to you to determine whether a particular feature or design element suits your application. Do you crave having a kettle drum or low-C piano note sounding as accurate as possible? Do you want to shake the mirror off the front window? Both are valid goals for a car audio system.

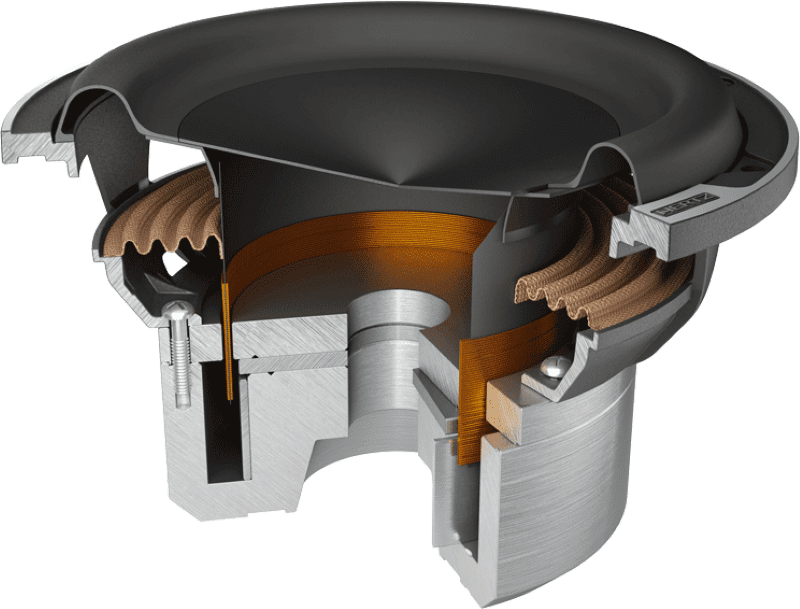

Basket Materials and Design

Let’s start with the foundation of a subwoofer: the basket or chassis. A subwoofer basket aims to align the components like the motor, voice coil, spider and cone. The least expensive subwoofers will have a simple stamped basket with little reinforcement in the form of curved features. Moving up from there, baskets with embossed or rounded-over edges are much stronger and more rigid. These designs can support heaving magnet structures without the risk of bending. Finally, we have cast baskets, which are the strongest designs and can support very heavy motor structures.

The tools required to create a basket, be it stamped or cast, are expensive. If the speaker manufacturer wants to reduce the cost of developing the product, they can use an existing generic design, though it can’t copy another product’s intellectual property.

Years ago, a fad involved adding mass to stamped baskets to increase their rigidity or reduce potential resonance. Installers and enthusiasts would add layers of Dynamat to the back of each spoke. The forces on a basket are in two directions. Gravity is by far the strongest force on a subwoofer basket. Imagine the force a 10-pound magnet, T-yoke and top plate exert on the basket as your vehicle hits a pothole. If the basket is too flimsy to support this, it will bend permanently. This results in a misalignment between the voice coil and the magnet assembly. The voice coil winding will contact the top plate and damage the woofer.

Forward and rearward forces from the magnet are also pushing and pulling on the cone. In comparison, these are minute, except perhaps for some extreme power SPL products. Even then, the magnet structure is a more significant concern.

The reality is that most car audio enthusiasts perceive cast-basket subwoofers as being better purely based on their physical appearance. Many products use stamped baskets shaped to look like their cast brethren. Ultimately, proper motor structure support is the goal.

Shallow-Mount Subwoofers

With the popularity of pickup trucks came the need for subwoofer solutions that could fit into extremely shallow areas. Historically, these subwoofers sacrificed excursion capability for minimized mounting depth. Today, many shallow 10- and 12-inch subwoofers offer just as much excursion and power handling as full-size ones.

Basket Cooling Features

The design of a subwoofer basket or chassis can affect its performance and longevity. A prime example is venting under the spider mounting plateau. The top plate can get warm, so allowing hot air to escape from the top surface can improve power handling. Many stamped subwoofers use vents stamped into the basket, while cast basket designs may include either slots or a design that uses a perforated plastic spacer for the spiders.

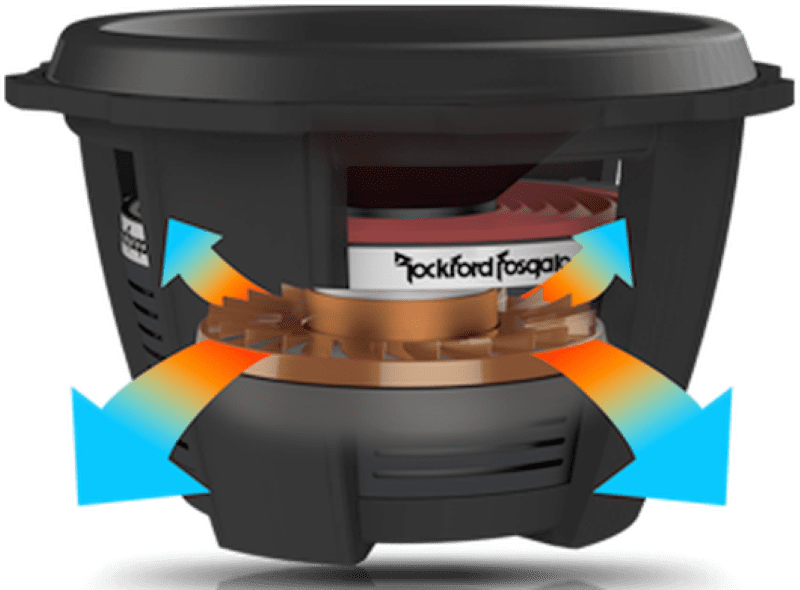

While we’re on the topic of cooling, Rockford Fosgate includes its Inductive Damping Heat Sink on its Power Series subwoofers. This finned copper element mounts on top of the top plate and improves heat transfer for enhanced power handling.

Magnet Materials

One of the heaviest components of a subwoofer is the magnet. The least expensive quality options might have a 10-ounce magnet, while some high-power options might have ceramic magnets weighing over 25 pounds. On its own, the weight or even the size of the magnet isn’t a feature that directly correlates to quality. However, a stronger magnet can improve efficiency. A larger magnet can help with power handling.

Most subwoofers use ceramic magnets, which are also known as ferrite magnets. These magnets are relatively simple to produce and not too expensive. They can put up with the high temperatures that large subwoofers have to endure. Rare earth magnets, made from neodymium, are much smaller for a given magnetic field strength. Depending on their quality, they can lose some of their magnetic strength when exposed to high temperatures.

We’re seeing more speakers and shallow-mount subwoofers using neodymium magnets inside the voice coil winding. This reduces size and weight at the expense of increased cost.

Speaker Wire Terminals

We should talk about electrical terminals while we’re on the topic of subwoofer baskets. The least-expensive option is a non-conductive cardboard or plastic tab with a pair of spade connectors attached. Your installer can crimp connectors onto the speaker wires and slide them onto the terminals.

Moving up, we find spring-loaded terminals. These are usually attached to a plastic tab or integrated into a custom-tooled mounting solution. While these are a seemingly simple design element, they cost a little more in terms of the raw components and the expense to tool the injection molding for the mounting solution.

At the extreme end of the terminal world are fully custom connection solutions. They can include unique spring terminals or terminal blocks with set screws. Once again, invoking these designs adds cost to the subwoofer as the parts are often one-off designs unique to that brand. When massive amounts of current need to be delivered reliably, these are often the best choices.

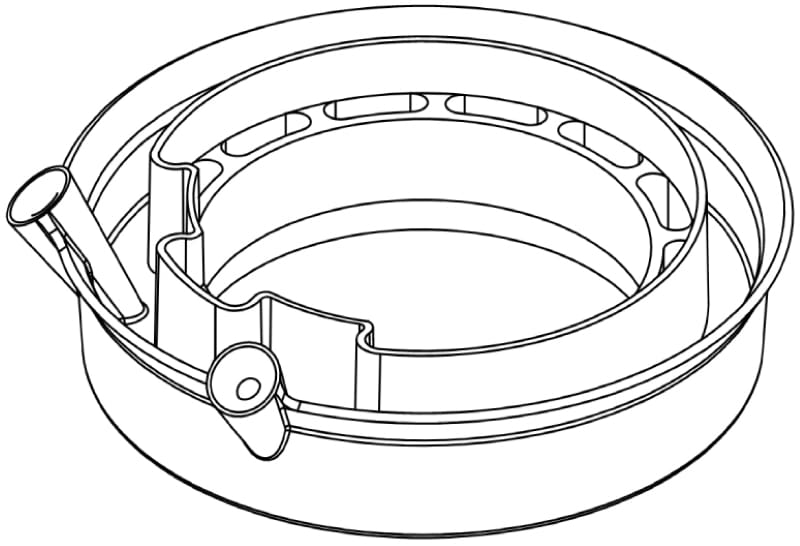

Mounting Gaskets and Hardware

It might seem like nothing, but including a mounting gasket with a subwoofer is essential. The seal between the enclosure mounting surface and the underside of the subwoofer basket is crucial to noise-free operation and maximum performance. Many subwoofers, even some that cost a lot, don’t include a mounting gasket. Ideally, the gasket should come already installed on the subwoofer. Yes, this process adds manufacturing expense but saves time and cost during installation.

Once again, something that seems insignificant but can save time during installation is for a subwoofer manufacturer to include mounting hardware. A little plastic bag with eight mounting screws that are sized perfectly for the subwoofer in mind will make getting your subwoofer system up and running quickly a breeze. Yes, it adds a few cents to the cost of the product, but it saves your installer time searching for the ideal hardware.

Subwoofer Grilles

As an extension of the discussion about mounting solutions, we should talk about subwoofer grilles. Protecting a subwoofer from damage when it is exposed is crucial to ensuring that it will last. If an object runs into the cone, it can be permanently damaged. Many subwoofers include perforated mesh grilles, or the manufacturer offers them as accessories.

Whether a manufacturer-provided grille is used or you have your installer construct a protection solution for your subwoofer, make sure it won’t interfere with operation. If the surround rubs on something, it will be damaged. This interference can also cause distortion.

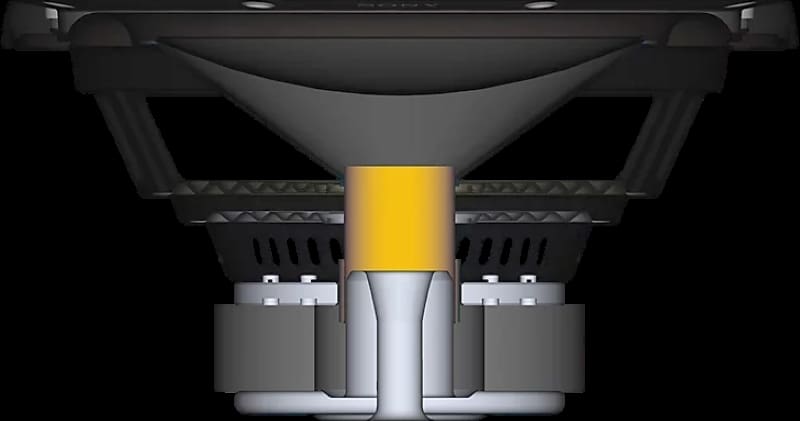

Vented Pole Piece Designs

The most popular cooling feature has been a vented pole piece. This design element involves an open channel that extends from the base of the T-yoke upward to underneath the dust cap. This vent allows hot air to escape from the inside of the motor assembly.

There is a situation where a pole piece or T-yoke vent can be an issue. For subwoofers designed for shallow mounting solutions, leaving room behind the subwoofer for air to enter and exit a pole-piece vent requires a gap between the back of the enclosure and the deepest portion of the motor structure. Some companies forego this vent to minimize mounting depth requirements.

Surround Designs and Materials

Let’s talk about subwoofer surround designs and materials. The least expensive subwoofers will use foam surrounds. These function well, but they can dry out and crack or degrade after a few years of exposure to the sun. A better solution is a synthetic rubber. Pure rubber also has issues with UV degradation, so materials like Santoprene or IIR-butyl are better options. It’s crucial, however, that the material doesn’t change dramatically in cold weather. The subwoofer won’t perform properly if the surround becomes stiff when temperatures go below freezing.

If you’ve ever stopped to consider the motion of a subwoofer cone relative to the shape of a surround, you’ll recognize that features built into the surround might improve linearity. Because the inside of the surround is smaller, it can, even at a microscopic level, compress laterally as the cone moves inward or stretch when it moves outward. Many subwoofers use ridges in their surround designs to improve linearity at high excursion levels.

You’ll find a few companies that stitch the surround to the cone. This connection is less likely to fail than the connection to the basket. So, while it can’t hurt, it’s often a cosmetic feature rather than one that improves reliability.

Cone Materials

A more controversial topic when it comes to subwoofer features that improve performance is cone material. Subwoofers are designed to play frequencies below about 100 hertz. As such, issues like cone and dust cap resonance aren’t the concern they are with midrange speakers. The only requirement is a subwoofer cone that can handle the forces exerted on it without being damaged. As such, a 10-inch woofer with a half-inch of excursion ability doesn’t need to be as strong as a 15-inch woofer that can move over 3 inches. So, polypropylene, paper, carbon, layered composites or even metals perform the same, as long as they can handle the forces exerted by the motor assembly. The same applies to dust caps, whether they cover the center of the cone or its entire surface.

There are some environmental considerations in terms of cone materials. Pressed paper cones could absorb humidity in extremely damp climates without a moisture barrier. Better designs will include a clear coating. All materials and designs should use materials that don’t degrade under prolonged UV exposure. Drying, cracking or fading are signs of ultraviolet degradation. If you aren’t sure about a product, ask to compare a new unit that was freshly removed from the package to one that has been on a display board for a while.

Designs That Increase Cone Area

Several companies have developed subwoofers that fit a specific dimension but include features significantly increasing cone area. Let’s look at three of the most popular examples.

First, Rockford Fosgate’s Vertical Attach Surround Technique moves the outer edge of the surround closer to the outside edge of the driver. In some applications, this can increase the driver’s effective cone area by as much as 25% with no changes to the mounting requirements.

Another area-optimized subwoofer would be the JL Audio W7 series. These drivers use a unique surround design that attaches to the outer edge of the basket after it’s secured to the enclosure. In keeping with the 8-inch theme, the 8W7AE-3 has an Sd specification of 245 square centimeters.

The king of effective radiating area for a given driver size goes to square subwoofers. Made popular by KICKER, their L-Series woofers make better use of the available space on the front of an enclosure. For example, the L7T82 8-inch woofer has an Sd value of 269 square centimeters.

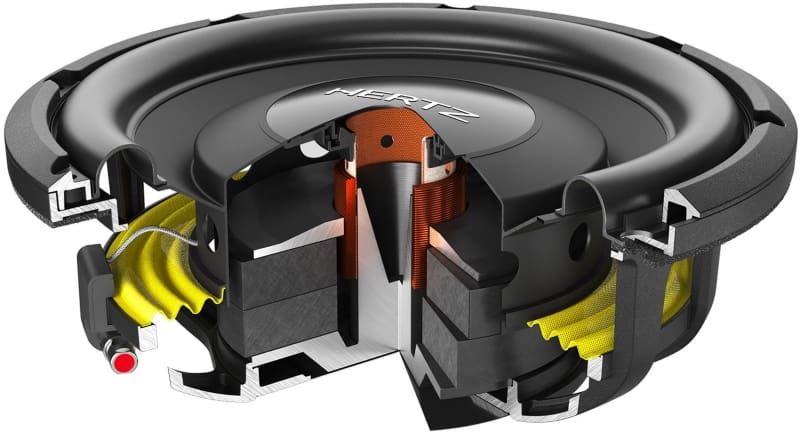

Voice Coil Sizes and Winding Layers

The voice coil is the heart of any subwoofer. If it fails, you won’t hear anything. Voice coils are nothing more than a length (or two or four) of wire wrapped around a former. The wire might be pure copper, copper-coated aluminum or aluminum. The choice of material doesn’t affect power handling or sound quality but might be chosen to add resistance to hit a target impedance.

The size of a voice coil affects performance in the context of power handling. A 2-inch winding that’s an inch tall won’t dissipate as much heat as a coil that’s 4 inches in diameter and 2 inches tall. The physical volume on the coil winding is a key contributor to power handling. If it overheats, the varnish on the wire will melt, and the coil will short or unravel.

While additional windings add more thermal mass to the voice coil, they have a negative effect of increasing the inductance of the winding. Added inductance opposes changes in the flow of alternating current. If the inductance is high enough, it can affect the midbass performance of a subwoofer. So balancing size, power handling, mass and midbass performance is crucial to the design process.

One design element that can improve voice coil performance is the use of flat-wound conductors instead of round. The flat conductors eliminate the gaps between round conductors to strengthen the magnetic density of the winding. This can translate into increased driver efficiency. There is also increased mass for a given set of outer dimensions. This can be beneficial or detrimental, depending on the goals for the subwoofer and the rest of the materials chosen. One thing is certain: Using a flat-wound voice coil will increase the cost of the subwoofer.

Voice Coil Former Materials

Another area that can affect the reliability of a subwoofer is the material used for the voice coil. We’ve seen everything from cardboard tubes (not unlike a paper towel roll) to anodized aluminum or synthetic materials like Kapton. These materials have different physical properties in terms of heat management and mass. The most efficient car audio subwoofers might convert two percent of an amplifier’s energy into sound. The rest is wasted as heat. As such, the temperature of a voice coil former might reach hundreds of degrees. It needs to remain dimensionally stable and rigid for the subwoofer to function correctly. Different materials help extract heat from the voice coil winding. Aluminum that’s been anodized black is a popular choice for high-power handling designs.

Some voice coils have vents at the top between where the winding ends and the coil attaches to the cone. These vents allow hot air to escape from inside the winding and improve power handling.

Voice Coil Winding Length

If you want a subwoofer that will play loudly, especially at low frequencies, the cone assembly needs to be able to move forward and rearward linearly. This specification is called Xmax. It describes the mathematical cone motion limit by subtracting the top plate’s height from the voice coil’s height and dividing it by two. So, if a driver has a 2-inch-tall winding and a 0.5-inch-thick top plate, the Xmax specification would be 0.75 inch or just over 19 millimeters.

Unfortunately, the motor structure is just one component in determining the usable excursion limit of a subwoofer. The second, perhaps of more importance, is the position where the driver becomes nonlinear. This could be caused by the spider or surround reaching its limit or when the voice coil starts to leave the gap. The Xmax10 specification is where a subwoofer reaches a distortion level of 10%. This is considered the upper usable excursion limit.

Bumped Bottom Plate

Part of designing a subwoofer with significant excursion capability is ensuring that the voice coil former doesn’t smash into the bottom plate (or T-yoke). If you’ve ever heard this, you know it sounds like a small hammer hitting a bench vice. In drivers with aluminum formers, it can roll over the end of the former and cause it to jam up in the gap when it tries to move upward. Subwoofers with fiberglass or Kapton formers can crack, causing the assembly to change shape and bind.

Using a bumped bottom plate is a straightforward design element that helps prevent this condition. Rather than being in line with the magnet bottom, a recess is cut or molded to add additional space. Subwoofers with bumped bottom plates were “cool” in the ’80s and ’90s, but it’s a common feature now. This feature is more likely found on a subwoofer with a single magnet than one with double- or triple-stacked designs.

Triple-Joint Reinforcing Designs

The joint where the voice coil, spider and cone are glued together is often called the triple joint. In many subwoofers, all three components are at the same point, while others have the spider mounted lower down the former. The exact location of everything depends on the design. As we’ve mentioned, the woofer cone needs to be strong enough to withstand the forces applied to it where it meets the former. Many companies will include injection-molded components at this joint to increase gluing surface area and add strength.

Pressure Relief Features Improve Linearity

A high-power subwoofer may be capable of moving forward or rearward over a range of more than 2 inches. As such, if pressure or a slight vacuum were to build up in the area, the driver would be less linear at high volume levels. Venting under the spider mounting plateau and the dust cap can prevent pressure changes, making the subwoofer more linear when pushed hard. Some drivers even have vents in the cone under the dust cap to release air pressure.

Suspension Component Selection

We’re starting to talk about implementing components that affect the Thiele/Small parameters of a subwoofer. There is no perfect subwoofer. Some are designed to be well-damped, while others have some intended resonance to increase output. The spider’s stiffness is the main component in determining the Equivalent Compliance (Vas) for a given subwoofer size. A stiff or narrow-diameter spider will typically result in a smaller Vas number. A soft or large-diameter spider will result in a higher Vas value. The compliance also affects the driver’s Qms or mechanical Q. Of course, no single parameter on its own serves as the final determining factor in the suitability of one subwoofer over another for a specific application.

A subwoofer’s Qts value (Total Driver Q) considers the electrical and mechanic Q factors. Low-Q drivers will have a smoother response, as the driver is less likely to resonate after the signal is removed. A high-Q driver might produce a little more bass, but this comes at the cost of a slightly less accurate sound with more ringing or overhang. Subwoofers designed to be more efficient and offer a little boom will usually have a somewhat higher Q, between 0.5 and 0.65. Low-Q drivers would be in the 0.3-0.4 range. Drivers with Qts values over 0.7 are typically designed for infinite baffle applications.

Some subwoofers use dual spiders to help keep the cone and motor assembly from rocking at high excursion levels. Implementing dual spiders usually increases Vas and Qms, but two compliant spiders might improve longevity. If the designer knows the cone will remain centered in the gap, they can tighten the gap to the top plate, which will improve efficiency.

Linear Versus Progressive Spiders

Two spider geometries are commonly available for car audio subwoofers. Linear spiders exert similar amounts of resistance to motion through a range of excursion levels. Progressive spiders have more compliance (move more easily) at lower excursion levels and then provide lots of control when the cone moves a lot. In reality, a spider will have a specific compliance curve that depends on the materials used in construction and the overall shape. The spider should prevent the voice coil former from bottoming on the back plate. While it seems counterintuitive, most high-end subwoofers have progressive-rate spiders. These days, “small-box” subwoofer designs are popular. As such, the compliance of the air in the enclosure plays a more significant role in the control cone excursion than the suspension. There are, of course, exceptions.

Tinsel Lead Management

Tinsel leads provide a flexible electrical connection between the subwoofer terminals and the voice coil winding. Finding tinsel leads sewn loosely to a spider is common practice to control their motion. There should be enough flexibility so the lead doesn’t affect compliance but enough control to prevent the leads from slapping into the cone. Other manufacturers will coat the leads in plastic or rubber and cut then to a very tight length tolerance to ensure that they don’t make noise. Tinsel leads floating around without proper management can short together or make a ticking noise as they bump into the cone.

In the early ’90s, a popular subwoofer line used carbon fiber woofer cones. The uncoated tinsel leads would run into these electrically conductive cones and, in extreme cases, burn a hole through the cone. The design also resulted in damaged amplifiers.

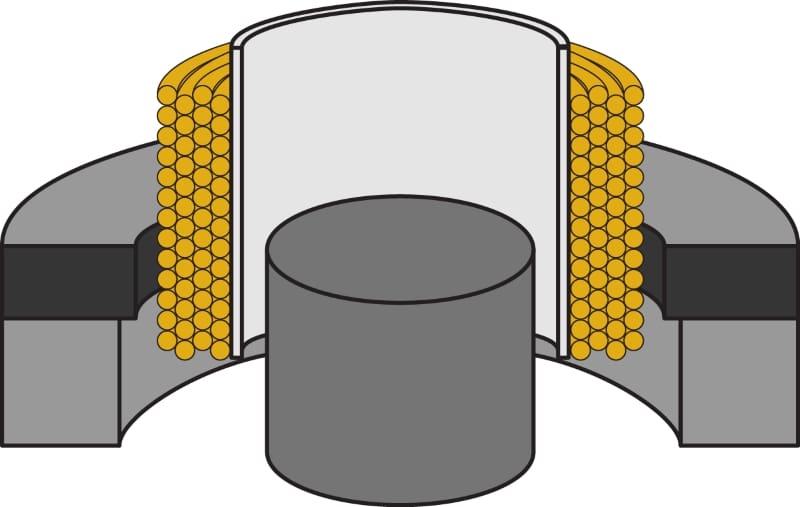

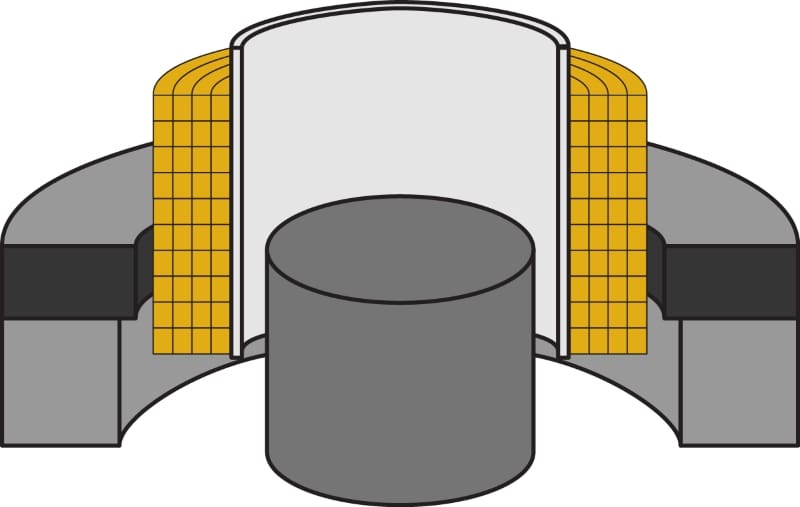

Shorting Rings and Copper T-Yoke Caps

Several options are available to help reduce changes in inductance based on subwoofer cone position. When a subwoofer moves outward, less of the voice coil might be inside the pole piece. As such, its inductance goes down, and higher-frequency performance improves. The opposite happens when the woofer cone moves rearward, and the midbass response worsens. A designer can add a shorting ring under the top plate or a copper cap on the T-yoke to reduce the overall inductance of the subwoofer coil and make these changes in inductance less significant.

Subwoofers with inductance management can play higher frequencies better, making them sound tighter and more dynamic. These drivers are also typically easier to blend with the midbass speakers in the front of the vehicle as the driver’s and the filter’s overall response is more predictable. Induction management is necessary for any subwoofer to be considered a high-end, sound-quality driver. Shorting rings can be made from aluminum or copper, with the latter being more expensive.

Dual Voice Coil Designs

Many subwoofers have two voice coil windings and two sets of external terminals. These windings can be wired in series, parallel or driven by different amplifier channels. Combining the suitable subwoofers with a particular amplifier will ensure that the system can play loudly and efficiently. From a performance benefit, dual voice coil subwoofers don’t sound or work better than their single coil brethren. They may, however, provide flexibility in optimizing available amplifier power.

Voice Coil Series or Parallel Switches

Getting the wiring on dual voice coil subwoofers right can be tricky for amateurs. Some companies include switches or plugs that make selecting between series and parallel wiring easy. The drawback to these features is an inability to feed each voice coil from a different amplifier channel. It’s rarely an issue, but it does come up with low-quality, non-bridgeable amplifiers.

JBL has a feature on some higher-end subwoofers called Selectable Smart Impedance that allows a single driver to present an amplifier with a nominal 2- or 4-ohm load, which can be selected with a chassis-mounted switch. SSI uses three 6-ohm voice coils to allow this level of flexibility. Of course, SSI is a patented design, so no companies outside the Harman group can use it without proper licensing.

ANSI/CTA-2031 Compliance

Just as the power specifications for car audio amplifiers got out of hand, so too have some subwoofer specifications. The ANSI/CTA-2031 standard describes testing criteria for car audio speakers and subwoofers. These specifications include continuous power handling, sensitivity, frequency response, excursion limits and dimensions, to name a few. Companies that confirm that the information they publish about their speakers complies with this standard have invested significant time and effort into ensuring that you get a quality product that functions precisely as described.

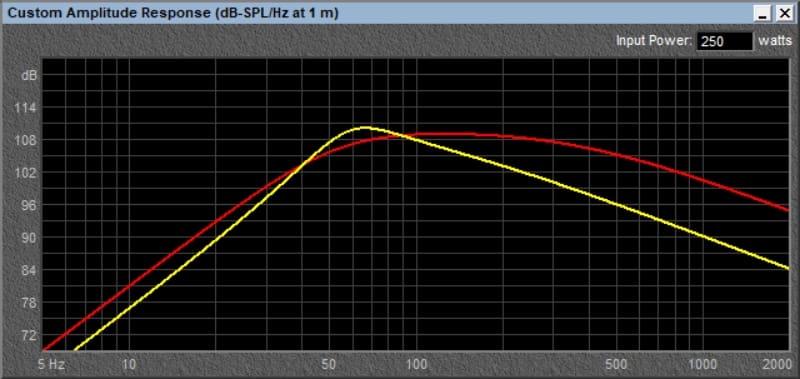

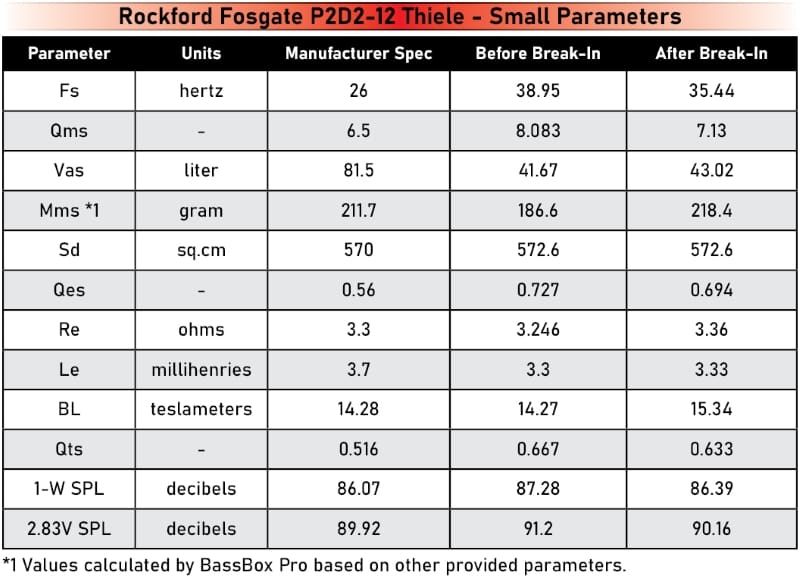

Suitable Thiele/Small Parameters

The last topic we’ll discuss is the suitability of a specific subwoofer for a particular application. Attempting to use a large speaker in an undersized enclosure is a recipe for weak bass and high distortion. When deciding which subwoofer will sound best for your car audio system, work with a reputable mobile enhancement retailer with the tools and experience to measure, model and design a subwoofer solution that will deliver the performance you want. We suggest working backward from the available space in the vehicle and then choosing subwoofers that will provide the most possible low-frequency output in that space. If your goal is maximum SPL, the criteria are similar, but rather than tuning the enclosure for maximum extension, it will be tuned higher or more efficiency.

For someone to design an enclosure, they need specifications that allow software applications like Term-PRO or BassBox Pro to simulate the frequency response, power handling and vent performance at different drive levels. These specifications are called Thiele/Small parameters. Each value describes a distinct characteristic of the cone assembly, suspension components and voice coil windings. With accurate data, an expert designer can create something that will perform well in your vehicle.

Thiele/Small parameters all work together to describe a subwoofer. As such, no single one stands out from the others as needing to be a specific value. As they say, there can be many ways to reach a destination. The right combination of design elements can provide impressive efficiency, but this often comes with a loss of low-frequency extension. Nobody, and we mean absolutely nobody, has found a way to defy the laws of physics regarding subwoofer design.

It’s crucial to note that the accuracy of the specifications is tied directly to the quality control standards of the manufacturer. If there are variances in cone mass, suspension compliance or adhesive application, the resulting subwoofer will behave differently from another sample. Consumers underestimate the importance of proper quality control during manufacturing.

Get Help Choosing the Best Subwoofer for Your Needs

Choosing the best subwoofer for a specific application depends on many variables. You might be on a budget and select something inexpensive with a foam surround, stamped steel basket, polypropylene cone and a single ceramic magnet to warm up a factory-installed audio system. Alternatively, you may want a subwoofer that can play as loudly as possible, so you’d choose something with a much larger double-stacked magnet assembly, a cast basket, enhanced cooling features, dual flat-wound voice coils and a strong cone to put up with more than 1,000 watts of power and high excursion levels. Lastly, you may want a driver with features like a shorting ring and copper T-yoke cap, a flat-wound voice coil, a progressive spider, a rubber surround and a compliant suspension to deliver highly accurate bass with very low distortion.

Adding a subwoofer to your car audio system is one of the best upgrades to improve its performance. Whether inexpensive, fancy or loud, this guide will help you work with a local specialty mobile enhancement retailer to pick a product that offers an excellent balance of value and performance to suit your expectations.

This article is written and produced by the team at www.BestCarAudio.com. Reproduction or use of any kind is prohibited without the express written permission of 1sixty8 media.

Leave a Reply